– Quick & Easy Installation.

– Beautiful & Modern Design.

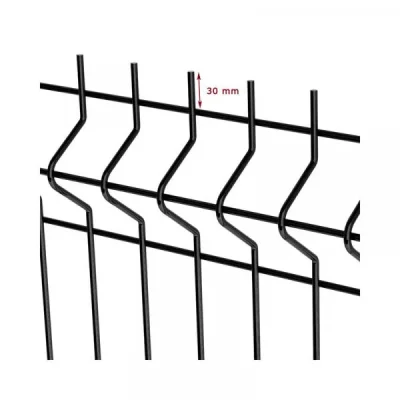

– Good Perspective, Unique 3D Shape, Smooth Lines.

– Strong Environmental Adaptability & Low Maintenance Cost.

– Diverse Color Options, The 3D fencing can be customized according to usage scenarios or needs.

– Products are professionally packaged to ensure safe transportation.

– Special pricing is available for bulk orders.

3D welded mesh fence panels are modern fence products with unique structures and excellent performance. This product is similar to our Rigid Mesh Fencing, but it uses a different bending method. First, the 3D fencing is meticulously crafted into mesh panels through precision welding technology.

Innovative horizontal curves significantly enhance rigidity, impact resistance, and stability. The product is durable and not easy to fade in various harsh environments. The 3D fence has the advantages of fast and convenient installation, beautiful and modern appearance, good perspective, and low maintenance cost. It is an ideal choice for a variety of applications such as residential, commercial, industrial, and public places.

We offer a wide range of customization options, including size, color (referencing the RAL color chart), and surface treatment, ensuring our fence panels perfectly match your project drawings and site environment, minimizing on-site modifications and improving construction efficiency.

We utilize advanced production processes and a strict quality management system to ensure that every batch of products meets ISO certification standards. At FENCE DEPOT, you can enjoy factory-direct pricing, eliminating intermediaries and effectively controlling project costs. Furthermore, we have a stable capacity for large-scale supply, ensuring your project schedule remains unaffected.

|

||

|

|

|

|

Height |

Wire Diameter |

Mesh Opening |

Panel Width |

|

830mm |

3.0mm – 6.0mm |

50*100mm 55*100mm 50*200mm 55*200mm |

2.5m or 3.0m |

|

1030mm |

|||

|

1230mm |

|||

|

1430mm |

|||

|

1530mm |

|||

|

1730mm |

|||

|

1830mm |

|||

|

2030mm |

|||

|

2430mm |

|||

|

2530mm |

|||

|

Material |

Steel | ||

|

Finish |

Galvanized; Powder-Coated ; Hot-Dip Galvanized | ||

|

Color |

Black, Green, or Customize | ||

|

As a professional 3D fencing manufacturer, we can customize various specifications of products according to needs or usage scenarios. |

|||

|

|

|

| Fence Wire Clips | Metal Fence Post | Post Caps |

Select high-quality steel wire that meets strength, toughness, and corrosion resistance requirements, such as galvanized steel wire. Stringent quality inspections are performed on the wire diameter, surface quality, and coating thickness.

The coiled galvanized steel wire, when passed through a high-precision automatic straightening machine, effectively removes its inherent curvature, achieving a straightness error of < 1 mm/m. Subsequently, it is cut to a specific length with high precision using a CNC length-cutting device, with the cutting length tolerance typically controlled within ±1 mm.

Using CNC bending equipment, galvanized steel wire is bent into the desired arc shape. The bending process requires extremely high precision from the bending machine, demanding precise control of the bending angle, radius, and material deformation. The bending angle error is controlled within ±0.5°, and the bending radius error is controlled within ±1mm, to ensure the accuracy and consistency of the arc shape.

Automated welding equipment is used to place the cut wire on the welding machine’s feed rack. The machine welds the intersections of the wires, forming strong welds. Full automation ensures uniform mesh size and weld strength.

After welding, the edges and welds are ground to remove burrs, oil, slag, and other impurities, preparing for subsequent coating.

Based on hot-dip galvanizing, a dense and robust powder coating with a thickness of approximately 80-120 micrometers is formed through a precise spraying process. This coating significantly enhances the fence’s corrosion resistance, UV resistance, and mechanical strength.

Check whether the dimensions of the fence panels meet the design requirements, including length, width, height, and bending angle. Check whether the welding points are firm and free from defects such as incomplete or missing welds. Check if the coating is uniform and smooth, and free from bubbles, scratches, or peeling.

Wrap the fence panels with plastic film or bubble wrap to prevent scratching or damage during transportation. Stack the fence panels on wooden or steel pallets and secure them with strapping for easy loading and unloading.

|

|

|

|

|

A. Yes. We can customize dimensions, materials, colors, and processes according to project requirements.

A. We provide free samples, which will be shipped within 7-10 days. You only need to cover the shipping costs.

A. It depends on the order quantity. We have large-scale production capabilities to ensure fast delivery according to project schedules.

A. The standard MOQ is one full 1×20′ container to ensure safe transportation. We can also accommodate smaller quantities if needed.

A. We will develop the most efficient production plan based on your order quantity and type. Communicating your needs as early as possible will help expedite the process.